E-posta biçimi hatası

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

The Role of Automatic Positioners in Modern Manufacturing: Enhancing Precision and Efficiency

In the fast-evolving world of industrial automation, automatic positioners are becoming essential tools for improving precision, productivity, and operational efficiency. These devices play a critical role in numerous industries, including welding, assembly, and machining. In this article, we will explore the importance of automatic positioners, their applications, and how they contribute to the modernization of manufacturing processes.

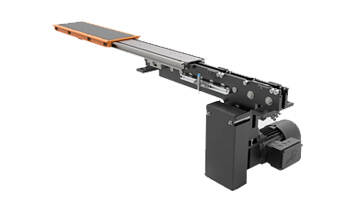

What is an Automatic Positioner?

An automatic positioner is a device that automatically adjusts and positions objects to the desired orientation for specific tasks. These systems are especially useful in industries where precise positioning is required for operations like welding, assembly, and machining. The positioner helps in reducing manual handling, improving the accuracy of operations, and enhancing the overall speed of the process.

Unlike manual positioners, which require operators to adjust the workpieces, the positioner rely on advanced mechanisms such as motors, sensors, and controllers to position the workpieces automatically. This automation reduces the potential for human error, speeds up the production process, and ensures that tasks are completed with high precision.

Types of Automatic Positioners

Automatic positioners come in various forms, depending on the specific needs of the task at hand. The most common types include:

1. Rotary Automatic Positioners

These positioners rotate the workpiece around a fixed axis, allowing for precise adjustments during processes like welding and inspection. The rotary positioner is commonly used in welding operations to position the workpieces at the perfect angle for welding, ensuring a uniform weld every time.

2. Tilting Automatic Positioners

These positioners tilt the workpiece, typically in a range of 0° to 90°, making them ideal for tasks that require the workpiece to be positioned at various angles. Tilting positioner are often used in assembly and welding processes where different orientations of the workpiece are necessary.

3. Dual-Axis Automatic Positioners

For more complex tasks, a dual-axis positioner allows for both rotation and tilting, providing enhanced flexibility. This type of positioner is perfect for tasks that require a combination of multiple angles to complete a process. They are commonly used in industries like automotive manufacturing and aerospace.

Benefits of Using an Automatic Positioner

1. Enhanced Precision

One of the primary advantages is the improvement in precision. These devices help ensure that workpieces are positioned exactly as required, which is critical in applications like welding or assembly, where even a slight misalignment can lead to defects.

2. Increased Productivity

By automating the positioning process, companies can reduce the time spent on manual adjustments. The positioner operates quickly and efficiently, leading to higher throughput and shorter cycle times. This increase in productivity can significantly lower the overall cost of production.

3. Reduced Labor Costs

Although positioner require an initial investment, they can help save on labor costs in the long term. Since these devices handle positioning tasks automatically, fewer operators are needed, and workers can focus on other aspects of the production process. This shift allows companies to reallocate their human resources to more skilled tasks.

4. Improved Safety

Automation in manufacturing has a direct impact on safety. The positioner reduce the need for workers to handle heavy or hazardous materials manually, which in turn lowers the risk of accidents. With automated positioning, the likelihood of human error or injury is greatly minimized, leading to a safer work environment.

How Automatic Positioners Are Used in Various Industries

Welding

In the welding industry, precision is paramount. The positioner are used to hold and rotate workpieces, ensuring that the welder can work at the optimal angle without any manual adjustments. By reducing human intervention, the positioner helps improve the quality and consistency of the welds, particularly in high-volume production environments.

For example, when welding large components, the automatic positioner can rotate the workpiece to ensure that each weld is applied evenly around the entire piece. This not only enhances the final product but also reduces the need for rework, saving time and resources.

Assembly

In assembly lines, positioner are used to position components for assembly processes. This is especially useful when dealing with complex parts that need to be aligned in specific orientations. The ability to adjust the position of the workpiece automatically allows for smoother assembly processes and reduces the chances of assembly errors.

Machining

In machining, the positioners help position the workpieces to the correct angle for operations such as milling, drilling, or turning. By ensuring the workpiece is held securely and positioned correctly, the positioner contributes to more accurate and efficient machining, reducing waste and improving the final product.

Robotics

In robotics applications, the positioner are often used in conjunction with robotic arms to manipulate parts with high precision. The positioners help ensure that the parts are oriented correctly for the robotic arm to perform tasks such as welding, painting, or picking and placing components. This synergy between robotics and positioners allows for highly automated production systems that can operate around the clock with minimal human intervention.

Choosing the Right Automatic Positioner for Your Needs

When selecting an automatic positioner for your manufacturing process, it’s important to consider several factors:

- Load Capacity: Ensure that the positioner can handle the weight and size of the workpieces you plan to process.

- Speed and Precision: Different positioners offer varying levels of speed and precision. Choose one that meets the demands of your application.

- Axis Configuration: Depending on your needs, you may require a single-axis, dual-axis, or multi-axis positioner. The complexity of your tasks will determine the best configuration.

- Integration with Other Equipment: Consider how the positioner will integrate with other systems in your production line, such as robotic arms or automated welding equipment.

The Role of Automation in Modern Manufacturing

The rise of automation in manufacturing has transformed many industries, allowing for faster, more accurate, and more efficient production methods. The automatic positioner is a key player in this transformation, helping to modernize manufacturing operations across various sectors. By integrating these systems into your production line, you can improve the quality of your products, reduce labor costs, and increase overall productivity.

One significant factor in the global supply chain is the growing demand for high-quality industrial equipment. For example, China ground rail systems are increasingly being used in automated factories around the world. These rails serve as the foundation for various automated equipment, making them an integral part of modern manufacturing processes.

Future Trends in Automatic Positioning Systems

As technology continues to evolve, automatic positioners are becoming smarter and more capable. Here are a few trends that are shaping the future of automatic positioning systems:

1. Integration with IoT (Internet of Things)

The integration with IoT technologies is allowing manufacturers to monitor and control positioning systems remotely. By collecting data from the positioners in real time, operators can make more informed decisions and optimize production processes for better results.

2. AI and Machine Learning

With the help of AI and machine learning, the positioner are becoming more adaptive. These systems can learn from previous operations, adjust for potential errors, and optimize positioning in real-time. This self-correcting ability can further reduce the need for human intervention, making manufacturing processes more efficient and reliable.

3. Energy Efficiency

As sustainability becomes a higher priority for many manufacturers, automatic positioners are evolving to become more energy-efficient. Newer models are designed to reduce power consumption while maintaining high levels of performance, helping companies lower their carbon footprint and reduce operating costs.

Conclusion

The automatic positioner is a vital tool in the modern manufacturing landscape, helping companies achieve greater precision, productivity, and safety in their operations. Whether you are involved in welding, assembly, machining, or robotics, investing in an automatic positioner can significantly enhance your production capabilities. As technology continues to advance, these systems will only become more intelligent and efficient, further driving the growth of automation in the industrial sector.